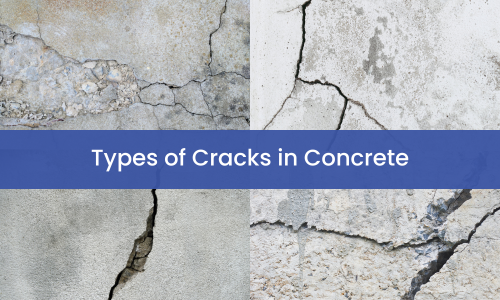

All concrete is eventually going to crack given its material composition and the environment it is exposed to. While it is impossible to prevent concrete from cracking over time, working with a reputable concrete contractor can prove to be valuable in understanding why cracks in your concrete are developing. Common types of cracks in concrete include:

- Plastic shrinkage cracks

- Map cracks (or crazing)

- Settling cracks

- Heaving cracks

- Spalling

Depending on the type of cracks and the severity, they may be correctable through repairs alone. However, in some cases total slab replacement will be necessary to restore the pavement’s strength and integrity. An experienced pavement contractor can determine which is necessary after inspecting the damage and its likely source. Here is a more in-depth look at the various types of cracks in concrete.

1) Plastic shrinkage cracks: fine, deep cracks located close to corners

Plastic shrinkage cracks emerge soon after the concrete cures and are typically found around any structure that intersects with the concrete slab. Support pillars and plumbing are two primary examples. Plastic shrinkage cracking occurs as moisture leaves the concrete during curing. As water evaporates out of the freshly laid concrete, it leaves behind voids (gaps) that represent structural weaknesses in the pavement. If the water-to-cement ratio is off while the concrete is drying, there will be an elevated number of voids present, leading to shrinkage and cracks.

Plastic shrinkage cracks can be prevented by mixing the right amount of water into the concrete mix and accounting for the temperature during curing. Elevated temperatures will accelerate the curing process and can cause the concrete’s surface to dry faster than the rest of the pavement.

Most plastic shrinkage cracks can be repaired as long as they do not impact the pavement’s structural strength.

2) Map cracking (crazing): shallow cracks spread out on the concrete's surface

Map cracking also emerges soon after curing and interlaces the surface like a spider web. These cracks are very fine and do not penetrate deeply into the pavement.

They develop in a similar fashion to plastic shrinkage cracks, as they are the result of poorly regulated curing. Specifically, crazing develops when the concrete’s surface dries faster than its deeper layers – which is common on hot days. What separates crazing and plastic shrinkage cracks is depth – map cracks do not penetrate deeply into the pavement’s surface. As such, they are a cosmetic concern only, though it’s a good idea to seal up any pavement affected by crazing to protect against water intrusion, and a reputable concrete contractor provide proper sealing.

3) Settling cracks: Severe cracks that run down to the concrete's base and may cause uneven pavement

Some types of concrete cracks are caused by factors that lie under the pavement. The concrete’s base, which is the soil the pavement sits on top of, must be properly compacted to optimize its load-bearing capacity. Reputable contractors will be sure not to skip or speed through this step as that could leave behind unstable soils that will shift and subside with time.

If that scenario happens, the ground will eventually slowly collapse under the pavement and will place additional stress on the concrete, causing deep cracks to develop. It is generally impossible to repair cracks caused by settling. Instead, the damaged concrete will need to be removed, the soil compacted and stabilized, and then a new slab will be poured.

4) Heaving cracks: Major fractures that may also cause uneven concrete slab

Heaving is the opposite of settling. Soil settlement causes the pavement to collapse on itself. Heaving refers to soil expansion due to certain types of weather. Winter weather in particular sets the stage for heaving. If water penetrates into the pavement and then freezes, it will exert expansion stresses on the soil and the overlaying concrete. The result is deep cracks that may split the slab and push parts of it up.

Like with soil settlement, heaving causes damage that cannot be easily repaired. The only fix is to replace the damaged concrete slab and protect the new concrete from water intrusion.

5) Spalling: Large chunks of material are breaking off the concrete

Spalls are chunks of concrete that have broken off of the pavement, which may expose the concrete’s deeper layers. Spalls vary greatly in size, and large spalls can put concrete at risk of further damage.

There are a couple of common causes behind spalls, including poor joint construction or rebar corrosion. While concrete is curing, expansion joints are cut into the pavement. These joints give the concrete additional room to expand and shift, which relieves internal pressures when the pavement is exposed to thermal expansion. If these joints are not properly installed, spalls may appear after intense heat or weather.

Rebar corrosion can also result in spalls. Steel reinforcement is chemically attacked by certain chemical compounds found in soil, or it may be compromised by exposure to water. When steel rebar corrodes, it produces chemical byproducts that expand out from the rebar and put major stresses on the concrete. As a result, spalls may form along the length of the corroded rebar,

Some spalls may be repaired with concrete patching, but the underlying issue will have to be corrected to ensure a permanent fix.

What Kinds of Concrete Cracks are Most Common in Houston?

Some types of concrete cracks are more likely to appear in Houston, where heat and rain pose a near-constant threat to pavement. Common concrete cracks in Houston include:

- Plastic shrinkage cracks – Any curing-related cracks are more likely to occur in Houston. With elevated temperatures during the city’s warm months, fresh concrete may dry a little too quickly if the wrong water-to-cement ratio is used.

- Settling cracks – Houston’s soil is characterized by huge tracts of expansive clays. When exposed to heavy rainfall, these clay-rich soils swell as they soak up water like a sponge. When they dry out, those clay-rich soils shrink and contract. This swell and shrink cycle – which feels endless during the wet season – puts intense stresses on Houston’s concrete.

- Cracks due to steel rebar corrosion – Houston features a lot of rebar-reinforced concrete. The Bayou City also features a lot of rainfall and salt – some of it suspended in the air and some of it in the soil. Given these conditions, it’s common for concrete in the area to develop cracks due to rebar corrosion.

Professional Concrete Contractors Can Correct Any Type of Concrete Cracking

There are many types of concrete cracks, and there are many potential causes behind them. It is often impossible for property owners to identify the cause behind their concrete’s damage. This is where an expert pavement contractor comes in. A reputable concrete crew has experience addressing a variety of cracks – thin, wide, deep, and shallow. This experience, along with their superior processes and materials, will ensure a long-term fix for your concrete pavement.

- How are Prime Coat and Tack Coat Used During Asphalt Pavement Installation? - December 19, 2025

- Houston Parking Lot Lifecycles: Is It Time to Resurface, Overlay or Replace Your Pavement? - December 5, 2025

- Why Should Asphalt Maintenance in Houston be a Priority for Property Owners? - November 14, 2025