Concrete Floor Replacement For Chemical Production Warehouse

A Chemical Production Warehouse Needed a New, Level Concrete Floor

A chemical production facility in Pasadena needed to replace a patch of concrete floor located in one of its warehouses. This multi-building complex was experiencing issues with the property’s subgrade. The shifting subgrade was causing obvious problems in the warehouse. An uneven floor was putting workers at risk, as storage racks were unsteady and at risk of falling over.

The American Paving team was brought in to stabilize the subgrade under the warehouse and replace a large part of the floor that had been compromised.

How the American Paving Team Solved the Facility’s Floor Problem

Nearly half of the warehouse’s concrete floor required replacement, but as extensive as the project was, American Paving was able to complete the job without disrupting the warehouse’s availability or operation. Here is what the team did to complete the project:

- Sawcut and extracted the failed parts of the floor. A large portion of the existing 8-inch concrete floor was already compromised and needed to be removed. The pavement team did so by sawcutting the floor and extracting all debris.

- Stabilized the subgrade and compacted it. With the subgrade exposed, the pavement team lime-stabilized and compacted it to restore its stability.

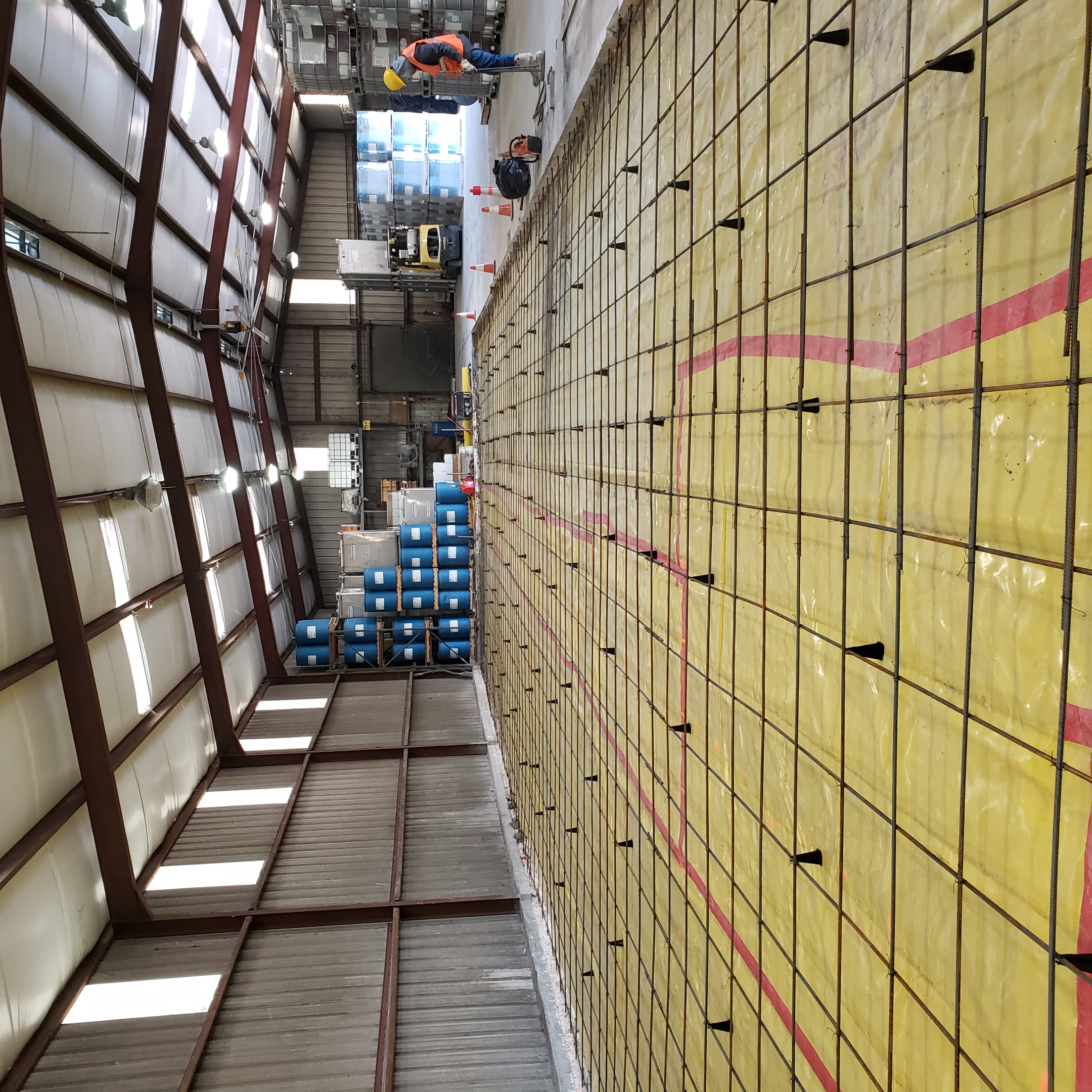

- Installed a moisture barrier. A moisture barrier was placed directly on top of the subgrade to prevent moisture from leeching from the subgrade into the concrete, and vice versa. This ensures the subgrade and concrete do not shrink or expand relative to each other.

- Installed concrete reinforcement bar. With the moisture barrier in place, the next step was to install a new grid of concrete reinforcement bar.

- Pumped in the new concrete and trowel finished it. Access into the warehouse was limited and mixer trucks could not enter. In response, the pavement team threaded a concrete pump into the warehouse. Fed by a pair of concrete trucks outside the warehouse, the pump allowed for precision pouring without interruption. Once pouring was complete, the pavement team provided a powered trowel finish.

If Uneven Pavement is Causing Safety Issues, Call the Houston Concrete Experts

Uneven pavement may be subtle, but even subtle pavement problems can pose major safety risks to active operational facilities. As the Pasadena warehouse project demonstrated, subgrade issues can manifest as serious pavement problems that require an expert team to resolve. In this instance, that expert team was American Paving.